CANDY TRAY PACKAGING MACHINES

Tishma Technologies’ Horizontal Cartoners are designed to handle all challenges in the candy industry. We provide state-of-art cartoning automation according to all safety and sanitary standards. Due to their precision, high speed (up to 500 CPM) and superior product handling, our cartoning solutions are widely used for secondary packaging of breath-freshening mints, vitamin candy, and pastilles blisters.

Improve your manufacturing process, achieve the highest possible production quality, and add value to your production chain with fast, reliable, and precise Side Load Cartoner for candy blisters that can be integrated with Top-Load Case Packer.

CANDY TRAY PACKING PROCESS

TRAY PACKERS

Good shelf-ready packaging makes in-store logistics more efficient and economic, causing your resellers to embrace and support your candy product. Most shelf-ready solutions are made of corrugated cardboard and typically they take shape of a tray. Shelf ready packaging allows consumers to easily identify and take your product from the shelf. It also allows retail workers to easily place the tray on the shelves and to easily dispose of it when it is emptied.

Tishma Technologies’ tray packaging machines provide maximum line efficiency and compliance with the strictest hygiene standards, which make them ideal packaging solutions for your candy products. Our tray packaging equipment is available with dual tray magazines, robotic pick-and-place tray filling system, race-track collation systems, and tuck or glue tray closing. When it comes to packaging speed, our Top-Load Tray packers are up to any challenge: they reach speeds up to 35 TPM (trays per minute).

Tishma Technologies is one of the leaders in special-purpose machinery engineering, due to its specialist expertise that lasts over 40 years. Global players, medium-sized producers, and small businesses trust our packaging machines and system solutions as they brought significant improvements to their value chain. Our employees are specialists with a vast understanding of packaging challenges you face. We have the right packaging equipment for all your requirements because we know your business and we know you.

Available with the Race-Track product collation system.

Available with tuck or glue tray closing.

Quick and easy changeover enables changing between carton sizes in a matter of minutes.

Washdown construction allows the machine cleaning and maintenance according to all sanitary standards.

CANDY TRAY PACKAGING MACHINERY

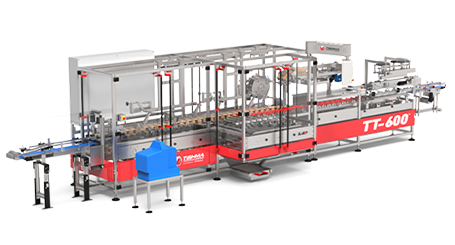

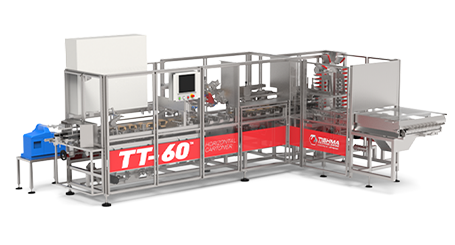

HORIZONTAL CARTONER TT-60

The TT-60 can reach speeds up to 100 CPM (cartons per minute) and it is great for multi-packing applications. It can collate products, and load them into a carton, or a display pack. Applications include pouches, blister packs, and numerous others.

CASE PACKER TT-1200

Horizontal Cartoners can be integrated with our TT-1200 top-load robotic case packer that features flexible speeds, multiple pack orientations; with a low case loading height and can reach speeds up to 20 cases per minute.

Safety and Quality Procedures

In order to be considered client-ready, every machine has to go through a set of checklist-based tests. Transparent testing documentation and clear testing criteria ensure machine compliance with all necessary requirements. No machine “leaves” Tishma Technologies without passing all the tests.