FLEX7 PACKAGES MANY TYPES OF CANDY

OR SNACK INTO POUCHES

– PACK STICK-PACKS AND SACHETS IN A STAND-UP POUCH –

The pre-made pouch is an excellent packaging for chips, nuts, or any snack. It is also widely used for wrapped and unwrapped chocolate candy, wafers, biscuits, and other types of confectionery. The pouch protects these products from moisture and keeps them fresh, but there is more to it. Stand-up pouches look great on the shelves, and consumers love them for their practicality. The use of flexible plastic pouches is a continuing trend in product packaging, and now you can pack any sweet and salty treats in a pouch with a single machine.

COMMON APPLICATIONS

- Cookies

- Popcorn

- Potato Chips

- Crisps

- Mixed Nuts

- Trail Mix

- Dried Fruits

- Peanuts

- Cashew Nuts

- Walnuts

- Pistachio Nuts

- Hazelnuts

- Seed Snacks

- Almonds

- Brazil Nuts

- Macadamia Nuts

- Marcona Almonds

- Gummy Candy

- Jelly Beans

- Hard Candies or Mints

- Wafers

- Bubblegum

- Lollipops

- Chocolates

PRE-MADE POUCH PACKAGING VIDEO

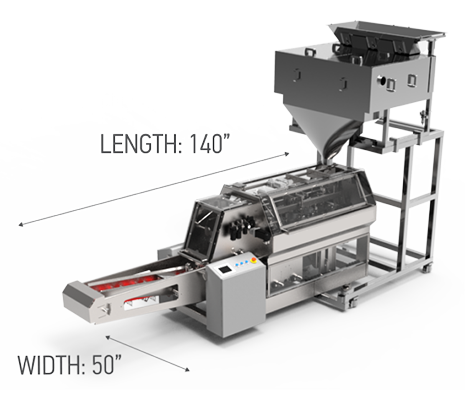

PRODUCT INFEED OPTIONS

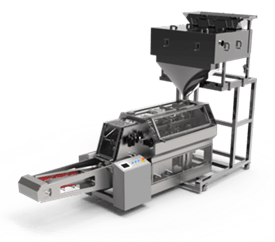

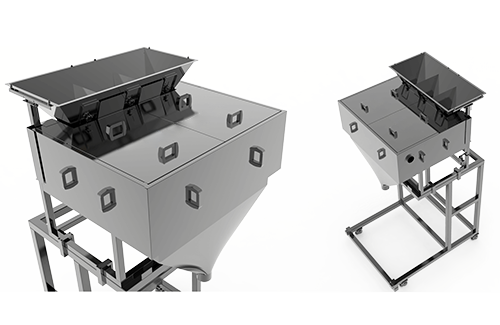

VIBRATORY COUNTER / FILLER

Suitable for candy and snack packaging applications where measuring precision and accuracy are essential. They are recommended for chips, crisps, peanuts, chocolate beans, biscuits, cookies, gummy bears, and other snack and confectionery products.

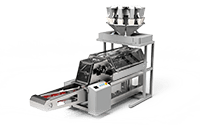

MULTIHEAD WEIGHER / SCALE

Allows more packs per weight of the product and more packs per shiſt due to improved weighing accuracy. We recommend it for complex, multiple-component products like trail mixes or candy mixes.

VIBRATORY COUNTER / FILLER

Suitable for candy and snack packaging applications where measuring precision and accuracy are essential. They are recommended for chips, crisps, peanuts, chocolate beans, biscuits, cookies, gummy bears, and other snack and confectionery products.

MULTIHEAD WEIGHER / SCALE

Allows more packs per weight of the product and more packs per shiſt due to improved weighing accuracy. We recommend it for complex, multiple-component products like trail mixes or candy mixes.

FEATURE OPTIONS

WASHDOWN

STRUCTURE

The washdown structure allows for cleaning the machine with a spray of water. No worries about rust!

NITROGEN GAS FLUSHING

Fills the pouch with nitrogen right before sealing the pouch. Nitrogen keeps your product fresh.

CODE/DATE

PRINTER

Prints a code/date on the pouch prior to pouch opening. Includes camera verification.

SEAL

COOLER

Cools the area of the pouch warmed by sealing. It is recommended for heat-sensitive products.

HOLE PUNCH /

DIE CUT

Punches or cuts a hang hole aſter pouch sealing, so the pouch can be placed on a retail display hook.

POUCH

DEFLATOR

Eliminates excessive air from the pouch. Removing oxygen from the pouch keeps your product fresh.

BOTTOM POUCH SUPPORT

Conveyor system provides additional support for heavier pouches, relieving pressure on the grippers.

VIBRATORY

SETTLER

Provides improved product settling inside the pouch.

WIDE RANGE OF POUCH TYPES AND SIZES

30-SECOND PUSH-BUTTON CHANGEOVERS

Flex7 is capable of handling a variety of pouch types within its pouch size range. With one push of a button, you can change over between pouch sizes in a matter of seconds! Flex7 allows you to select the best premade pouch type for your sweet or salty product, regardless of material finish.

- Make your product stand out on a shelf with a stand-up pouch

- Utilize sealed pouch for lower net weight packaging format

- Let your consumer see the actual product with a windowed pouch

- Use a zipper/resealable pouch to keep the candy or snack fresh until the next use

TISHMA TECHNOLOGIES

ROBOTIC AND AUTOMATED PACKAGING EXPERTS

Get the best solution from a reliable packaging machine manufacturer. Tishma Technologies is devoted to developing long-lasting, compact, automatic packaging systems with competitive prices.